A wall fence production line typically involves a series of processes and machinery to manufacture precast concrete wall panels used for fencing and wall construction. The production line may include various stages such as concrete mixing, panel casting, reinforcement installation, curing, finishing, and packaging. Here is an overview of the components and processes involved in a typical wall fence production line:

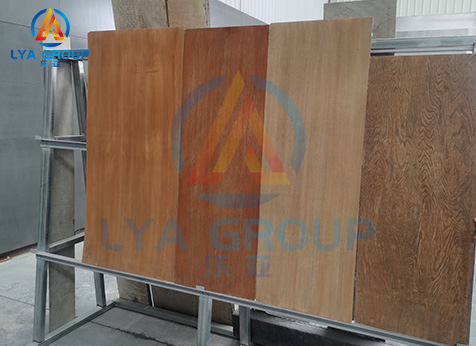

This is a flexible panel display effect

Concrete Batching Plant: Where raw materials such as cement, aggregates, water, and additives are mixed to create concrete batches.

Moulds: Customized molds used to shape the concrete into wall panels of specific sizes and designs. These molds can be made of steel or other materials depending on the production requirements.

This is a display of finished wall panels

Reinforcement Installation: Steel reinforcement bars are placed within the panel molds to enhance strength and durability.

Concrete Pouring: The mixed concrete is poured into the molds and compacted to remove air voids and ensure uniform density.

Curing: The freshly poured concrete panels are cured in a controlled environment to achieve the required strength and durability.

Finishing: Surface treatments, textures, patterns, and colors may be applied to the cured panels based on design specifications.

Quality Control: Inspection of the panels for dimensions, appearance, and structural integrity to ensure they meet quality standards.

Packaging and Storage: Once the panels have been inspected and approved, they are packaged and stored for transportation or on-site installation.

A wall fence production lin

Designing an efficient wall fence production line requires careful planning to optimize workflow, minimize waste, and ensure consistent quality. Automation can be incorporated at various stages to increase productivity and reduce labor costs. Additionally, considerations such as energy efficiency, environmental impact, and safety standards should be taken into account during the design and operation of the production line