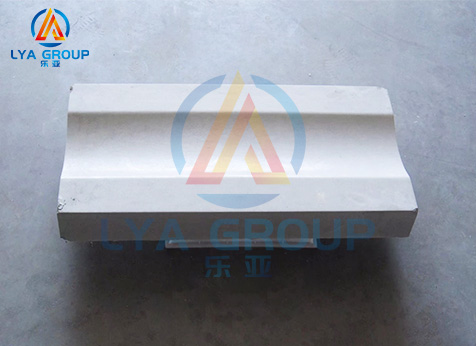

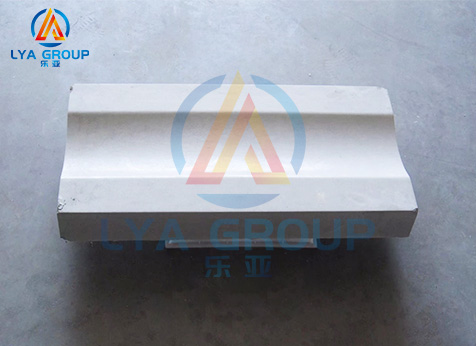

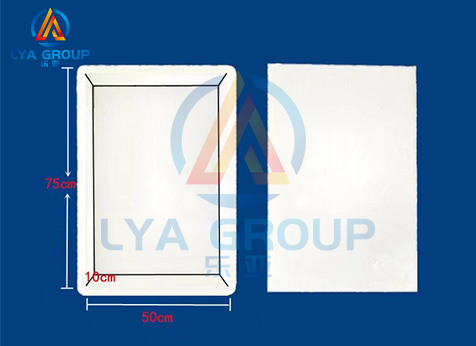

1. Variety designs and size for the kerbstone mold.

2. Size: 1000X250X150mm, 750X250X150mm, 1000X300X200mm, 500X250x150mm

3. Plastic mould, strong and finishing surface.

4. easy to cast and demould.

5. lifespan: more than 1000 times casting with proper care.

6. It is cheap by using the plastic mold to make the wall tile. and profit can be returned fast in short time.

7. Curbstone are versatile materials that can be used in the following spots: Lawns, Plant boxes, Gardens, Pathways, Driveways, Ground covers

Installing these pavers to create stunning appeal is called “curbing.” Accordingly, landscaping contractors use appropriate curbing or edging machines that allow them to cut out flower beds or create trenches for the edging pavers to be installed quickly. They normally have both electric- and gas-powered edging machines to suit specific edging installation needs.

1. At 2 mm thick, our concrete curb molds are more robust and less likely to deform, ensuring consistent quality in curbstone production and reducing the rate of defective products caused by mold deformation.

2. Our concrete curbing molds can be reused between 80 to 200 times, significantly exceeding the lifespan of ordinary molds. This high reuse rate greatly reduces the frequency of mold replacement, lowers production costs, and enhances the sustainability and efficiency of production.

3. Utilizing a new, reinforced type of PP material provides excellent corrosion and wear resistance. This choice of material ensures that the molds maintain stable performance over prolonged use, even in harsh environments, extending the mold’s lifespan and improving return on investment.

4. LYA GROUP offers various styles of concrete curbstone molds to meet different production needs. This diversity allows clients to respond flexibly to the requirements of various projects, reducing the time and costs associated with custom mold fabrication. We also offer services to customize concrete curbstone mold styles based on specific needs for bulk order clients. This customization ensures that the molds perfectly meet the unique requirements of special projects, enhancing product applicability and client satisfaction.

We are dedicated to delivering products of exceptional quality. Our strict quality control processes ensure that every product that leaves our facility meets the highest standards, providing you with reliable and long-lasting solutions.

Our commitment to offering competitive prices gives you a distinct advantage.allowing you to maximize your budget without compromising on quality or service.

Your satisfaction is our priority. We go above and beyond to understand your unique needs and tailor our solutions accordingly.

We stay at the forefront of industry trends and technological advancements to provide you with innovative solutions. Our research and development team is constantly exploring new ideas and refining our products to meet the evolving demands of your business.

We believe in building long-term partnerships based on trust and mutual success. Our commitment to open communication, transparency, and integrity ensures that we work collaboratively with you to achieve your goals and surpass your expectations.

We understand the importance of timely delivery. Our efficient logistics and reliable supply chain management enable us to deliver your orders promptly, ensuring that you receive your products when and where you need them.

We are committed to environmental sustainability. We prioritize eco-friendly manufacturing processes and materials, reducing waste and minimizing our carbon footprint. By choosing us, you align your business with responsible and sustainable practices.